What is an Anti-lock Braking System (ABS)?

Imagine driving on a wet road when suddenly, a deer jumps out in front of your car. In a vehicle equipped with an Anti-lock braking system or ABS (a system that prevents wheel lockup during braking), when you slam on the brakes to avoid hitting the deer, the system will automatically regulate the braking force to prevent the wheels from locking. This action allows you to steer around the deer safely, avoiding a potentially serious accident.

Let us explore more about how ABS works, its components, and the benefits it offers to drivers and passengers alike.

What is an Anti-lock Braking System or ABS?

The Anti-lock Braking System (ABS) is a complex safety feature that keeps a vehicle’s wheels from locking up when the brakes are applied suddenly or with too much power. If you must use emergency brakes, ABS helps you retain control of the steering wheel, reducing the chances of an accident.

The sensors and motors inside the wheels that make ABS work keep track of the speed of the wheels in real-time. The device will briefly lessen the force and stop a wheel about to lock up. This way, if it feels that the wheel is about to lock up, it can still turn, allowing you to maneuver around obstacles even while braking hard.

ABS doesn’t always ensure a shorter stopping distance for a vehicle. A vehicle with ABS will probably stop faster than one without it on most surfaces. However, ABS triggered by forceful braking may lengthen the stopping distance in slick conditions while providing you steering control.

Keeping a safe, efficient, and legally compliant business requires fleet managers, owner-operators, and truckers to know about vehicle safety features. Modern vehicles, especially commercial trucks, include the Anti-lock Braking System (ABS) as one of its fundamental safety features.

How does ABS work?

ABS monitors wheel rotational speeds via speed sensors. The system has a controller, pump, and brake valves. Speed sensors alert the system when rapid braking threatens wheel lockup. It regulates braking fluid pressure to the damaged wheel(s), letting the driver maintain control and maneuver around obstructions.

As discussed, the anti-lock braking system consists of wheel speed sensors and valves. In an emergency, ABS technology automates the brake pumping procedure, giving you time to focus on navigating the car to safety. Anti-lock brakes work to keep your truck’s wheels from locking. It allows you to continue steering during a sudden stop. Have a look at how these components carry out the task of keeping a vehicle safe on the road:

- Wheel speed sensors that track the speed of each wheel are fixed on a vehicle’s wheels. The Electronic Control Unit (ECU) interprets every sensor’s signal. The ECU signals the valves of the corresponding wheel(s) to lower the brake pressure, and the valves close when the speed sensors determine that the speed of that wheel(s) is significantly decreasing in comparison to the others.

- Following this, the wheels begin to accelerate once more. The ECU receives this signal and sends it to open the valve, increase the brake pressure, and apply the brakes.

- Until the use of brakes becomes easier, the cycle repeats.

Let us understand this better with this example:

You are driving a fleet vehicle down a wet roadway. Due to the wetness on the road, the truck’s tires lose some of their grip. The traffic in the front abruptly stops moving because of an accident. Instinctively, you slam on the brakes, trying to bring the vehicle to a rapid halt to avert a collision.

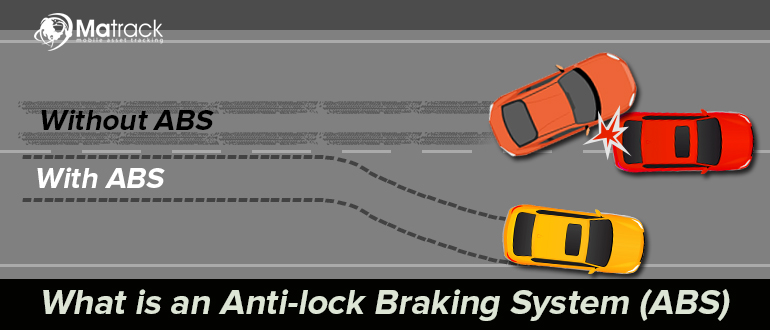

Without ABS

In a vehicle without anti-lock brakes (ABS), an abrupt braking action would probably lock up at least one wheel since the tires would have less friction with the wet road. When the truck’s wheels lock, it starts skidding uncontrollably, making it hard for you to manage the vehicle. If it doesn’t come to a halt because of friction or because it hits anything else, it will keep going in the same direction. Without anti-lock brakes (ABS), semi-trailers have a better chance of jackknifing, which is particularly dangerous in wet and icy environments.

With ABS

Trucks with anti-lock brakes (ABS) might respond differently to the same circumstances. Hard braking would trigger the anti-lock braking system (ABS) instantly. Each wheel’s speed sensor would pick up on the sudden slowdown and alert the ABS controller, warning that a wheel is ready to lock up. To avoid locking up, the ABS controller would instruct the system to adjust the braking pressure applied to that particular wheel.

So, the vehicle can keep its grip on the road even when the brakes are engaged since the wheels keep turning. You can control the truck’s direction using this traction, which might let you avoid accidents by swerving or sliding to a halt. The characteristic pulsating of the brake pedal reassures you that the ABS will actively prevent wheel lock-up when engaged.

The Outcome

ABS improves the truck’s adherence to its course, helping to prevent skidding and reducing the likelihood of an accident. You can make a well-informed choice on handling the unexpected halt, such as turning around the accident if there is adequate room or gently braking within your lane.

This example shows how ABS improves commercial vehicle safety, especially in bad weather or unexpected traffic. ABS prevents wheel lock-up, protecting the vehicle, cargo, driver, and other road users. It shows how improved safety technologies like ABS are essential in the transportation business, making roadways safer for everyone.

Types of Anti-lock Braking Systems

There are many varieties of Anti-lock Braking Systems (ABS)

All Anti-lock Braking Systems (ABS) help keep the vehicle under control when braking hard, but engineers create different forms of ABS to address specific vehicle designs and requirements. When making educated decisions on the capabilities and maintenance needs, fleet managers, owner-operators, and truck drivers can benefit from a better understanding of these categories. One of the following types of anti-lock brake systems is very useful for commercial vehicles:

Four-Channel, Four-Sensor ABS

As far as we know, this setup is the full-featured ABS. The system can keep tabs on and adjust the performance of each wheel separately with separate sensors and channels in the ABS controller. This arrangement provides the best control and efficacy in avoiding wheel lock-up. It benefits trucks and trailers used for commercial purposes, which are notorious for unequal load distribution and require precision management.

Three-Channel, Three-Sensor ABS

One of the three channels in this setup monitors each of the three wheels—the front and back—and the axle. The back wheels are controlled and monitored using only one channel. This system effectively prevents lock-up and offers excellent control to the front wheels, but it may not respond as tailoredly to the rear wheels as a four-channel system would. Earlier models, lighter to medium trucks, and other vehicles typically use this configuration, where precise control of the rear wheels is not as important.

One-Channel, One-Sensor ABS

The simplest anti-lock brake system (ABS) requires one sensor, often mounted on the back axle and one channel in the controller. It coordinates the rear wheels to prevent and regulate skidding. Older or less sophisticated automobiles commonly have this kind, since they do not justify the expense of installing a more advanced ABS. While multi-channel systems outperform it, having some is still safer than having none at all.

ABS for Trailers

Specialized anti-lock brake systems equip trailers to ensure that articulated trucks do not slide or jackknife. These systems may be separate from the tractor’s ABS and operate on their own, or you can integrate them so that the trailer’s ABS works with the tractor’s system. For better safety and control when towing large or heavy objects, you must have anti-lock brakes (ABS) on a trailer.

Enhanced Stability Systems

Some car manufacturers have developed more sophisticated stability control systems that build on the foundation of ABS. Roll Stability Control (RSC) lessens the likelihood of a rollover, and Electronic Stability Control (ESC) prevents oversteer and understeer while navigating corners. These systems improve vehicle control in various settings, increasing safety by utilizing extra sensors and algorithms.

When emergency braking or on rough roads, a vehicle’s ABS type affects its handling and safety. Because safety and dependability are paramount, commercial vehicle fleet management, maintenance, and driver training must understand ABS types. Technology is improving anti-lock braking and vehicle stability systems, making transportation safer for all.

Benefits of Using ABS Technology

- Enhanced Safety: One of the advantages of ABS is that it offers enhanced security. The system reduces the chance of skidding and prevents wheel lock-up, helping the driver keep control of the vehicle in emergency braking conditions. Commercial vehicles need more space to stop completely because of their size and weight. It is of the utmost importance.

- Decreased Stopping Distances: Anti-lock brakes (ABS) help shorten stopping distances on wet and slippery roads by allowing the driver to apply the full force of the brakes while maintaining traction. Keeping the cargo and other drivers safe and preventing rear-end crashes is crucial.

- Improved Vehicle Control and Stability: Thirdly, Anti-lock Braking Systems (ABS) improve vehicle stability and control during braking, which is particularly useful for trucks hauling big or unevenly distributed loads. Remember to keep your balance and control in these kinds of situations.

- Compliance with Regulations: Some nations demand that commercial cars have ABS as a component of their road safety requirements. These regulations are complied with. Fleet managers and owner-operators reflect their dedication to safety standards in the legality of their vehicles for road usage and their commitment to compliance.

- Insurance Benefits: Vehicles with ABS often have cheaper insurance costs due to the reduced likelihood of accidents. Fleet operators and owner-operators can save a lot of money in the long run.

Final Thoughts

ABS significantly reduces the risk of fatal crashes harming passengers by preventing the wheels from locking while you apply the brakes. Various authorities have emphasized the effectiveness of the anti-lock braking system. The US government has made anti-lock brake systems mandatory, considering them vital safety equipment.

Despite being a crucial development, ABS brakes should not give you a false sense of security. To fully benefit from anti-lock brakes, you must refrain from bad driving habits such as speeding, tailgating, and sleepiness. Your reaction speed will increase when you drive defensively. It is particularly essential for handling an emergency safely. Anti-lock brakes and other safety equipment function best when driven cautiously and sensibly. Don’t expect ABS brakes to make up for careless driving.

Frequently Asked Questions

Q. Is ABS Good for all commercial vehicles?

ABS is a great automotive safety feature. It helps drivers avoid accidents by providing stability and control during emergency or heavy braking. This technique reduces skidding and road veering, improving safety.

Q. Can I Retrofit ABS to My Vehicle?

ABS cannot be retrofitted into a non-ABS vehicle. ABS installation involves complex braking system upgrades that are not possible after production. ABS is now standard in most new automobiles, demonstrating its relevance in vehicle safety.

Q. How Can I Tell If My Vehicle Has ABS?

Your owner’s handbook should include your vehicle’s safety features, making it easy to check for ABS. You can either contact the vehicle’s manufacturer or check your dashboard for an ABS light that momentarily glows when you start it